agricultural services

Maurer-Stutz, Inc. (MSI) is recognized throughout the Midwest for delivering practical and innovative Agricultural Engineering solutions. Our team of agronomists and engineers draws on deep, diverse experience across private industry, extension, and government service. As a NRCS Certified Technical Service Provider, we support USDA Technical Assistance Programs while offering clients a single source of expertise from planning through construction.

Working closely with other MSI specialists, our agriculture staff provides comprehensive services for livestock and poultry facilities, crop processing and handling, irrigation, drainage, and on-farm storage. From system evaluations and facility planning to compliance support and conservation practices, we deliver knowledgeable recommendations and integrated solutions that help producers design, manage, and sustain operations that are efficient, resilient, and built for the future.

OUR SERVICES

LIVESTOCK SYSTEMS

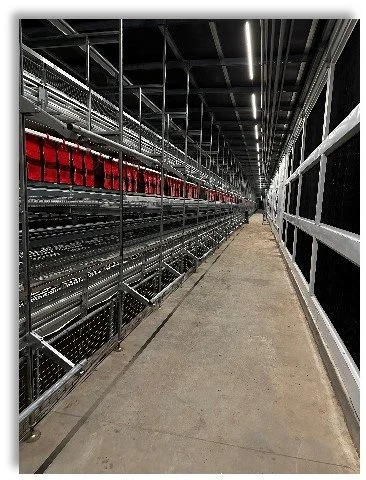

We design and plan modern dairy, beef, swine and poultry facilities that may include manure storage, transfer, and treatment that improve efficiency, meet regulations, and that manure can be utilized for energy or fertilizer—all tailored to your farm’s needs and future goals.

-

We provide planning, design, and permitting for livestock facilities, delivering efficient, compliant, and future-ready solutions for beef, dairy, swine, and poultry operations.

-

We design durable manure and wastewater storage systems—including earthen, concrete, and steel structures—to ensure safe, reliable operation.

-

We design pumps, channels, and piping systems that move manure and wastewater safely and efficiently between barns, storage, and treatment facilities.

-

We engineer treatment solutions such as separation, composting, and anaerobic digestion to maximize resource recovery and environmental performance.

-

We engineer treatment solutions such as separation, composting, and anaerobic digestion to maximize resource recovery and environmental performance.

-

We develop certified nutrient management plans that balance crop needs, protect water quality, and meet state and federal compliance requirements.

SPECIALTY CROP ENGINEERING

From greenhouses and packhouses to optimized cold storage and water reuse systems, we engineer specialty crop facilities and processes that boost quality, cut shrink, speed throughput, and keep you ahead of regulations and market demands.

-

Shrink and lost customers erode your margins quickly. Even a 1% improvement in shrink, dehydration, or rejects will improve profitability directly. We work alongside you as a grower, packer, or processor. We integrate industry experts and your technology vendors to understand the full system - from field through storage and shipping - reducing waste while consistently delivering top-tier and trustworthy quality.

-

Real improvement doesn't happen overnight. It takes a consistent and thoughtful approach. We walk arm-in-arm with you through growing, harvest, storage, packing, and shipping seasons to assess practices, implement targeted changes, monitor results, and refine execution. By coaching your teams to learn from observations and outcomes, their knowledge and improvements stick. Performance steadily moves toward operational excellence.

-

From new facilities to retrofits and remodels, we help you work alongside industry suppliers to plan and design storage, packhouses, and specialty crop facilities aligned with your operation and markets. We analyze load-in, airflow, humidity, temperature, structural systems, energy use, etc. to protect quality, increase capacity, reduce shrink, and deliver strong, measurable returns on investment.

-

We aid you in conducting hands-on evaluations of field operations, handling lines, cooling systems, and workflows to identify bottlenecks, labor inefficiencies, energy waste, and sources of shrink. More importantly, we help train your teams, coach execution, and track progress-turning recommendations into durable operational improvements over time.

-

Clean produce, efficient water use, and regulatory compliance are essential. We design practical post-harvest wash-water systems-from recycling and treatment lagoons to zero-discharge solutions-that reduce water use, support higher throughput, and minimize compliance risk. Improving your operations reliability and confidence with customers, neighbors, and regulators alike.

OTHER SERVICES

Safe ag-chemical handling, bulletproof SPCC plans, money-saving energy audits, precise ventilation design, and expert construction observation with full record drawings—practical engineering solutions that protect your farm, lower costs, and satisfy every inspectors, agencies, and other partners on your project.

-

We design safe, no-nonsense chemical and fertilizer storage and mix/load pads that keep you (and the environment) protected. Containment that actually works, easy clean-up, and layouts that fit your sprayer and tender trucks so you’re legal, safe, and ready to roll when the weather breaks.

-

An SPCC plan shouldn’t just sit in a binder. We walk your farm, size your tanks, map containment, and write plans that are simple, practical, and actually pass inspection. If something ever spills, you’ll be glad we made containment easy and bullet-proof.

-

Lights, fans, pumps, and coolers can eat profit. We come in, measure what’s really running, and show you exactly where the dollars are leaking out. Most farms we audit knock 15-40% off their power bill with changes that pay back in 1-3 years.

-

Good air keeps cows, crops, and people happy. We design natural and mechanical ventilation systems that move the right amount of air without wasting energy—whether it’s tunnel venting a barn, cooling a packhouse, or keeping potatoes breathing right all winter.

-

We’re your eyes on the job—not the general contractor. We make regular site visits, check that everything’s built to our plans and specs, catch issues early, and keep detailed records. When it’s time for state inspections, cost-share paperwork, or final reimbursement, our photos, reports, and record drawings make the process smooth and painless.

Connect with Our Agricultural Team

Have questions or need expert guidance for your agricultural project? Fill out the form below, and our team will get back to you shortly.